Malfunctions are deadly. They only happen when you are firing your weapon, and since you will only be firing if your life is under immediate threat, any stoppage is a critical event.

The primary requisite of the self-protection firearm is reliability. 100% reliability is not attainable in any mechanical instrument made by man, and 99% is unacceptable. I wouldn’t own a weapon that failed with one shot in every hundred. So we try for as near to 100% as possible. A major part of this is stoppage reduction by prior checking and maintenance.

With self-loading weapons [semi/full auto] the magazine is critical to reliability..... a £800 pistol can be rendered inoperable by a £10 magazine. In this article we are going to examine how to maximise the reliability of the magazines, thereby, reducing the chances of a stoppage while fighting for your life.

MAGAZINE SELECTIONNever trust your life to cheap, aftermarket magazines. This is false economy. You need at least six magazines for a minimum training/operation regimen, so magazine costs are hardly a budget-breaker.

Most pistols come with two mags, so you will need to obtain at least four more. I’d suggest buying the manufacturer’s own brand, which are the most likely to give most reliable service in their weapons. There are numerous aftermarket mags on the market, often at very cheap prices. I’d avoid them, with the exception of Meg-gar magazines. Meg-gar actually makes mags for many leading gun companies, and their products are top notch.

When you purchase a new magazine don’t just assume it will work. As ever, the mantra for the CQB operator is “check, cross-check, recheck”

Ensure that the magazine falls free when the release-button is pressed; with slide forward, as well as locked to the rear. Do this with mags empty, partially- and fully loaded. With the muzzle in a safe direction, hand cycle a full load of your normal carry ammo through the weapon. Finally, fire at least three full loads through the mag, using rapid and slow-fire, and ensuring that the slide locks back on an empty magazine. Only after this trust your life to the mag.

TRAINING MAGAZINESIn any decent firearms training program magazines are likely to be harshly treated. They will be dropped onto gravel, trodden on as you fire & move, lie in mud, sand or wet grass. Such mags get dinged, bent and weakened. For this reason we teach our guys to have two separate sets of magazines, operational and training.

Operational mags are kept immaculate. One in the weapon, two on the belt is the minimum you should have, and these are treated as if your life depends on them, for obvious reasons.

You should then have a similar number of training magazines, and these should be clearly marked, as “training only” Glock sell an orange training magazine which is ideal for the purpose.

[Glock training mag]

[Glock training mag]Alternatively, they sell orange baseplates to denote training mags. I was given a load of these, as well as one of the full orange mags by my friends in Federal Law Enforcement training. After the UK handgun ban I gave them to Clint in RSA.

Paint, or, nail varnish will do to mark training magazines.

By the way, if you do have a stock of cheapo “Brand X” mags, you can use them in training. Coping with malfunctions should be a regular part of training, and cheap mags can provide valuable lessons.

MODIFYING MAGAZINESTo reduce wear and tear on your training magazines it’s a good idea to add a pad of rubber, or other resilient material, to the base, to cushion impact when dropped.I teach retaining the magazine during malfuntion drills, but many people let the mag drop free. Of course, even if you avoid dropping your mags, accidents happen, and over an extended training cycle those mags can suffer.

I had many of my magazines fitted with a rubber pad by my local shoe repair shop.

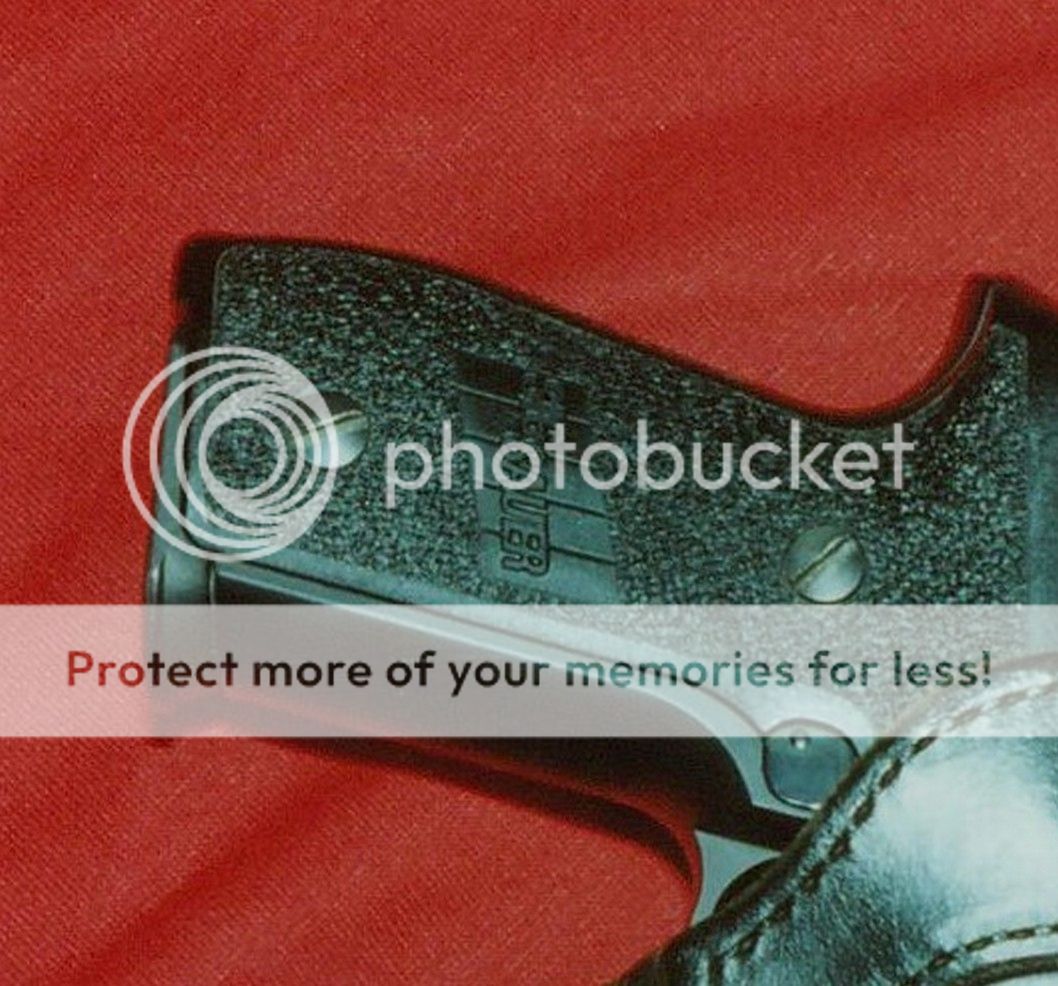

[Rubber basepad added to P7 mag]

[Rubber basepad added to P7 mag]Some weapons have an optional base pad. For example, the SIG 9MM has a thicker plastic pad which does the job. I obtained these for my SIG-228 mags.

[Plastic baseplate adds little to the overall length, but cushions impact well]

[Plastic baseplate adds little to the overall length, but cushions impact well]The Mag-pac magazine for the Colt .45 came with a fitted thick baseplate [as well as a very efficient follower design] The Mag-pac was the favourite of Colonel Cooper

[Mag-pac baseplate]

[Mag-pac baseplate]When buying spare magazines go for those with a good anti-corrosion finish. Many pistols and accessories, especially older designs, have a blued finish, which, while visually attractive is prone to rust. Warren Buttler, a Federal Air Marshal told me that the standard finish on the SIG would rust overnight in the Philippines. SIG have a more resistant “K-coat” finish that is a better option.

While visiting the Heckler and Koch factory we were shown the then new Hostile environment finish on their forthcoming USP pistol. I asked what finish they used on their most expensive pistol the P7, to be told that it was standard blueing. I was in the process of arranging for my P7, and other blued magazines to be plated with the NP-3 finish, probably the best anti-corrosion treatment available.

More modern designs now come with great finish, such as that H&K hostile-environment coating, and the terrific Tenifer process on the Glock. Again, don’t let the mags be the weak point in the system.

EXTENDED MAGAZINESMost such extra-capacity mags have reliability problems. Exceptions include the SIG 20 round mag, which I've used extensively with no issues whatsoever.

Also the Glock “+2” aftermarket baseplate increases capacity by two rounds, and fits their 9mm mags.

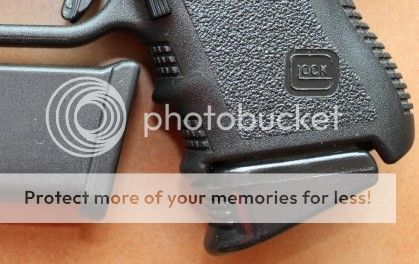

[Glock "plus 2" on right, compared with standard base]

[Glock "plus 2" on right, compared with standard base]By the way, when using these I regarded them as “plus one” and only added one more round. These baseplates also act to protect the mag when dropped as well.

MAINTAINANCE PROCEDURE A comprehensive maintenance programme, based on three levels:

1] Daily cleaning & Inspection

2] Range Cleaning.

3] Armourers' Maintenance.

Even if you haven’t fired the weapon, give it a wipe down at the end of the day. Similarly, wipe the magazines. They have been carried close to the body, in possibly humid or rainy conditions.

After a range session, the weapon, including mags should be thoroughly cleaned, using the recommended procedure.

CLEANING MAGAZINES

The first thing is to know how to disassemble the mag. Don’t assume you know how, unless you’ve been trained on the specific model. I once saw a military chap rip the baseplate right off a Colt magazine, because he thought it came apart like his familiar Browning [he was an officer, by the way].

As a safety precaution, always wear your range eye-protection when stripping magazines, as the spring can fly free with force.

[SIG-228 mag disassembled. Note the toothpick used to remove baseplate]

[SIG-228 mag disassembled. Note the toothpick used to remove baseplate] Clean the parts by soaking them in white spirit [Turps], taking care to observe room ventilation factors. Thoroughly dry the parts with a clean 4x2 cloth. Lubricants and ammo don’t mix, so it’s not usually a good idea to oil the parts; however there is a product called Dri-slide, a molybdenum suspension, which reduces friction while keeping the inner parts dry and non-sticky.

More on weapon reliability

hereCHARGING THE MAGAZINEWe term filling the mag with ammo “charging”, as we keep the word “load” for the procedure of actually loading the weapon itself.

When using high-capacity magazines, consider carrying weapon charged one round less than capacity. Mike Izumi, a firearms instructor and aerospace engineer, told me that doing this decreases magazine spring pressure by 30%.

When charging high-capacity mags it can be easy to lose count of rounds, especially with MP-5 mags for example; so fill the mag until you can’t get another round in, then take the top round out.

Some military authorities insist on “resting” magazines, to avoid the springs “taking a set”. Well, here’s an extract from an article in American Handgunner Magazine, by John S Layman.

“Recently, I read an article in a gun magazine suggesting you rotate your magazines so the ones not in use can "recover and rest." The same author uses the phrase "spring-set" to describe weakness of a spring because it was compressed for a long time. Hogwash. There's nothing further from the truth. Springs don't care how long they're compressed and don't require rest, recreation or even a vacation from time to time.

To put this one to rest, you have to understand creep. Creep is the slow flow of a non-ferric metal like copper, brass and lead under force. At temperatures outside of a furnace, steel doesn't have any appreciable creep. Under most conditions, steel flexes and then returns to its original shape. When pushed past its elastic limit, steel will bend and not return to its original shape. All designers of well-made magazines make sure the spring never approaches the elastic limit when the magazine is fully loaded. Honest. This means the spring will not weaken when the magazine is fully loaded -- not even over an extended time. Like 50 years. American Handgunner recently ran a story about a magazine full of .45 ACP that had been sitting since WWII and it ran just fine on the first try. So there you go.”

To sum up, buy top-class magazines, keep your operational magazines separate, maintain your kit, and, finally, check, cross-check and re-check.